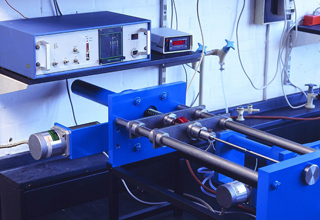

Tensile Test Machine controlled via Mini-step Driver

|

At the Technical University of Denmark (DTU), a JVL Controller and Mini-step Driver are used to control a very precise tensile testing machine.

The metallurgy laboratory at the Technical University of Denmark (DTU) performs many tensile tests on various types of material in conjunction with research and teaching activities. In one specific instance the tensile force was up to approximately 3 tons, with a velocity range of 10-9 to 10-4 m/s exerted on the test specimen. The laboratory had a need for a motor type and control system that both could operate very slowly during tensile tests which are carried out over a period of several days, yet operate sufficiently fast enough to reset the machine when new test specimens were to be mounted. It was therefore decided to use a control system consisting of a single step motor controller, JVL type SMC20 which has a step-pulse output, and a JVL Mini-step Driver type SMD41 with a variable number of mini-steps per full step (10, 25, 50 or 125). Using this system configuration, the velocity can be controlled both by changing the step-pulse frequency and by changing the number of mini-steps per full step via 2 of the Controller's outputs. In order to operate at even lower motor revolutions than that obtainable using the highest step resolution and lowest step frequency, an additional switch was configured so that instead of being driven by step pulses from the step-pulse output, the Mini-step Driver SMD41 was driven |

|

Tensile test set-up at the Technical University of Denmark, showing motor, planetary gear, worm drive and spindle.

using pulses from an ordinary output set to operate on/off at a given frequency. At the highest step resolution this gives the facility for extremely precise and smooth operation at very low velocities. The tensile test machine has now proven its reliability in daily operation over a long period of time and is an excellent example of versatility in the application of step motors.

|

JVL A/S Deutschland Moltkestr. 24 DE-72762 Reutlingen Deutschland

Tel: +49 7121 1377260 Fax: +49 7121 1377317 E-mail: sales@jvl.dk

Tel: +49 7121 1377260 Fax: +49 7121 1377317 E-mail: sales@jvl.dk