Coloplast using JVL Control in test Set-up

|

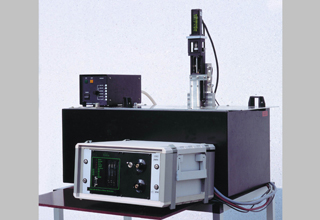

Plastic components are endurance-tested in special test set-up

The Danish company Coloplast A/S manufactures a wide variety of clinical and hospital products. The company has recently constructed a special test set-up for testing product plastic components.

The test set-up moves the test objects so that they are subjected to the same forces and deformation that they experience under normal use. The test objects are simultaneously submerged in a liquid solution that exposes them to the chemical environments they also experience in practice. Test objects are bent using linear motion produced by a servo motor that drives a spindle. The motor is controlled by an AC servo-controller AMC12B, for which JVL has also developed the required software. The velocity of motion (rpm) and displacement (revolutions) can be adjusted as required using 2 potentiometers in a control box. Two photo-sensors provide safety end-of-travel limits, one of which also functions as a zero-point position. |

|

The complete test set-up

The set-up has been developed to test a specific component, but can also be adapted and used for many other types of component. JVL is pleased to have contributed to the solution of this application at Coloplast A/S.

|

JVL A/S Deutschland Moltkestr. 24 DE-72762 Reutlingen Deutschland

Tel: +49 7121 1377260 Fax: +49 7121 1377317 E-mail: sales@jvl.dk

Tel: +49 7121 1377260 Fax: +49 7121 1377317 E-mail: sales@jvl.dk